Invest in cleanliness and stability — choose the Flexco H-Type Primary Cleaner!

Would you like to spend less time and money on conveyor maintenance?

An efficient primary cleaner can significantly reduce costs associated with conveyor downtime and maintenance. The durable and reliable Flexco H-Type requires minimal maintenance time.

Its high primary cleaning efficiency greatly reduces the workload of the secondary cleaner, minimizes carryback, and extends the service life of conveyor rollers and belts.

The Flexco H-Type cleaner is the key to minimizing conveyor maintenance costs.

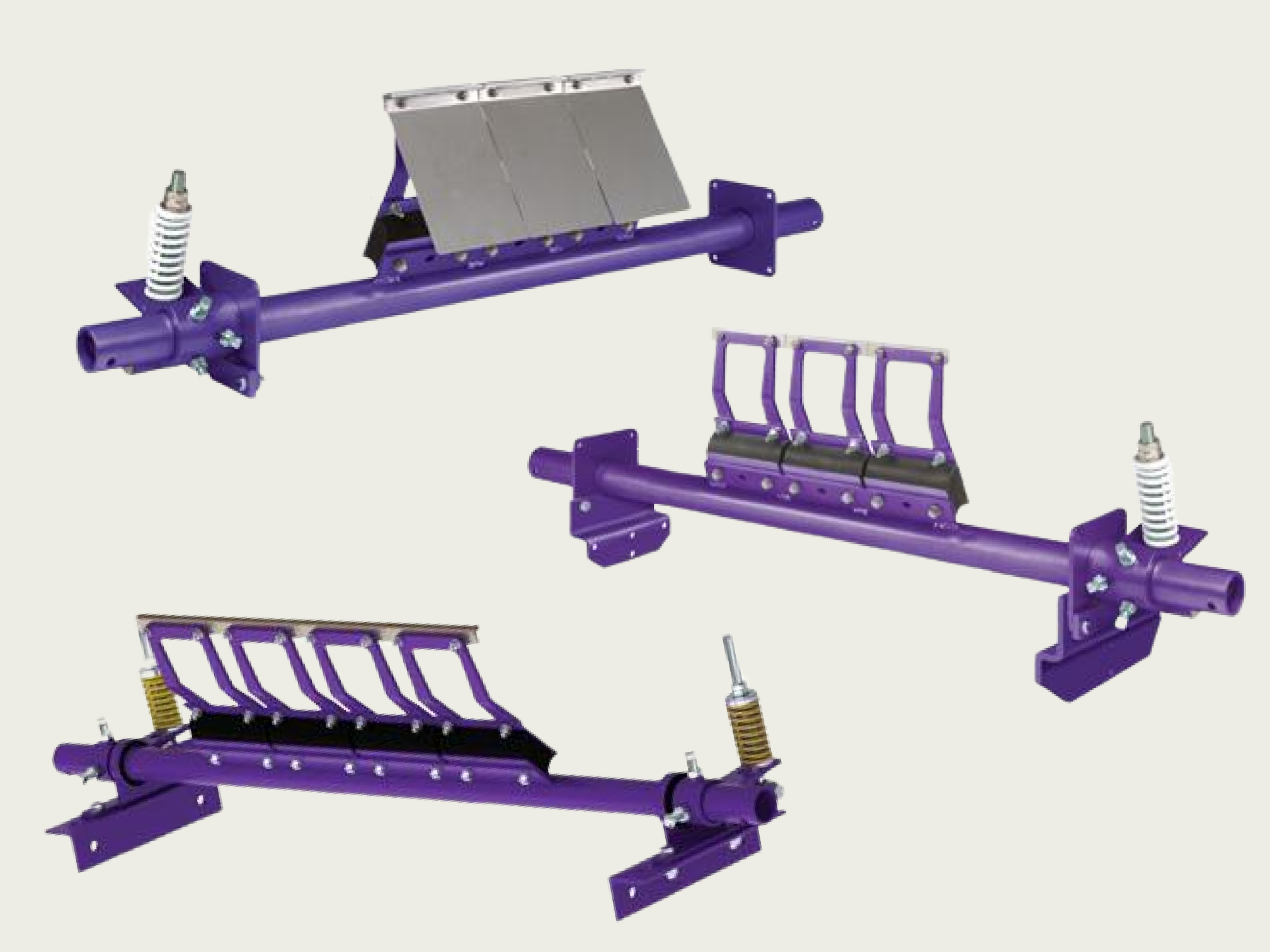

Power and versatility

• For belts 450 – 1800 mm wide, spliced with hot vulcanization.

• For conveyors with belt speeds up to 5 m/s.

• For pulleys with diameters from 250 mm, including crowned pulleys.

• Available with wear-resistant polyurethane blades or tungsten carbide blades that last several times longer!

Fast maintenance

No unnecessary tools — simple, quick, and safe — minimum downtime, maximum efficiency.

Real savings

Fewer maintenance stops + less belt and roller wear + less frequent replacement of cleaners and rollers = higher profits.

For tough conditions:

Perfectly suited for quarries, cement plants, steel mills, and coal industry facilities — wherever conditions are harsh and quality and time are critical!

.jpeg)

Comments