Laser processing of coated belts by Beltimport: precision, efficiency, and reliability

Laser processing of coated belts by Beltimport is a highly precise and efficient method for creating perforations and various types of engravings on toothed and flat belts with different coating materials.

This technology allows for programming laser parameters such as power, speed, and focus to ensure high precision and the required hole shapes (round, oval, rectangular) and cuts of various lengths and configurations. This provides extensive possibilities for engineering solutions, enabling belts to be precisely tailored to specific production process requirements.

This is particularly useful when belts need to be adapted to operating conditions or customized for special tasks (e.g., vacuum transportation and product fixation, film pulling, packaging, cables, etc.).

Additionally, for different coating types such as Linatex, Polyurethane, Viton, Correx, and Tenax, the perforation process can be optimized depending on the material's requirements and operational conditions.

Laser processing ensures holes with minimal dimensional deviation and positioning accuracy of up to 0.1 mm, without mechanical impact on the material. This preserves the functional properties of the coating, such as wear resistance and flexibility, especially when it comes to materials with high operational requirements.

Belts processed with laser technology are widely used in various industries, including packaging, food processing, paper, woodworking, and textiles. Each of them has specific requirements for materials, construction, and belt properties to ensure maximum efficiency and reliability. Each industry may require individual belt customization, such as special patterns to improve grip, or additional anti-static and wear-resistant properties.

Beltimport has established its own production of coated traction belts under the Bibelt brand. Flat and toothed belts from Forbo, Optibelt, and Megadyne serve as the base for coating applications. Available coating materials include transparent polyurethane, yellow polyurethane, and Linatex.

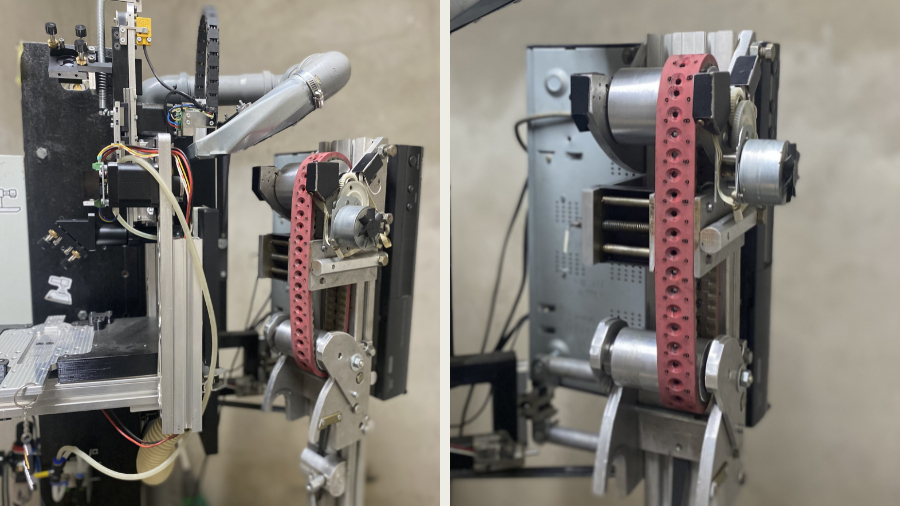

Additionally, an in-house laser processing machine provides significant advantages in lead times and pricing without compromising quality. Unlike ordering finished products from foreign manufacturers, which involves transportation, customs procedures, and international logistics challenges, in-house processing ensures faster delivery and competitive pricing.

Fast execution and timely delivery help prevent production downtime and unnecessary costs due to waiting periods, ensuring seamless manufacturing processes.

With Beltimport, you get the optimal balance between reliability and cost, allowing businesses to focus on growth rather than lengthy international shipments and customs procedures.

Comments