Metal conveyor mesh belts: reliability, flexibility, and durability for industrial processes

Metal conveyor mesh belts: reliability, flexibility, and durability for industrial processes

Metal conveyor mesh belts - are specialized transport belts made of metal wire or strips of round or flat metal wire where traditional conveyor belts cannot perform. Their design provides excellent resistance to high temperatures, mechanical loads and aggressive environments, making them indispensable across various industries.

Applications of metal conveyor mesh belts

Metal mesh belts are widely used in the following industries:

- food processing (baking, freezing, frying, cooling);

- heat treatment of metals;

- glass, ceramic, and porcelain manufacturing;

- electronics production (soldering, drying);

- surface treatment (sandblasting, parts washing);

- pharmaceutical industry

- automated warehouse and material handling systems.

Thanks to their unique properties, metal conveyor belts ensure high wear resistance, and hygiene compliance.

Main types and range of metal conveyor belts

The modern range of metal mesh belts includes a wide variety of designs, differing in weave shape, wire diameter, edge types and connection methods.

The most common types are:

Wire Mesh

Wire Mesh (also called rod network belts) — nets made of bent wire that are intertwined. It provides good air permeability and convenience in use on long conveyor lines. They can be straight or swivel.

Advantages:

- flexibility and adaptability to different forms of transportation;

- uniform heating or cooling of the product;

- optimal circulation of air or liquids.

Applications: baking cookies, drying, cooling bottles, applying glaze.

.jpeg)

Eyelink Nets

Eyelink nets (loop or mesh nets) are made of metal rings that are intertwined with each other through crossbars. They create an even crossbar. Used to connect wire loops. Ideal for transporting heavy products.

Advantages:

- high resistance to loads and impacts;

- easy to clean;

- suitable for high-temperature processes.

Applications: oven baking, pasteurization, meat processing, can washing, freezing.

.jpeg)

Spiral Woven Mesh

These grids are made of alternating left and right spiral turns, connected by crossbars. This spiral design (alternating) helps reduce tracking problems caused by the tape being biased to one side.

Advantages:

- ideal solution for harsh conditions;

- high wear resistance;

- resistance to thermal deformation.

Applications: processing of glass containers, transportation of hot parts, easy connection, sintering of materials.

.jpeg)

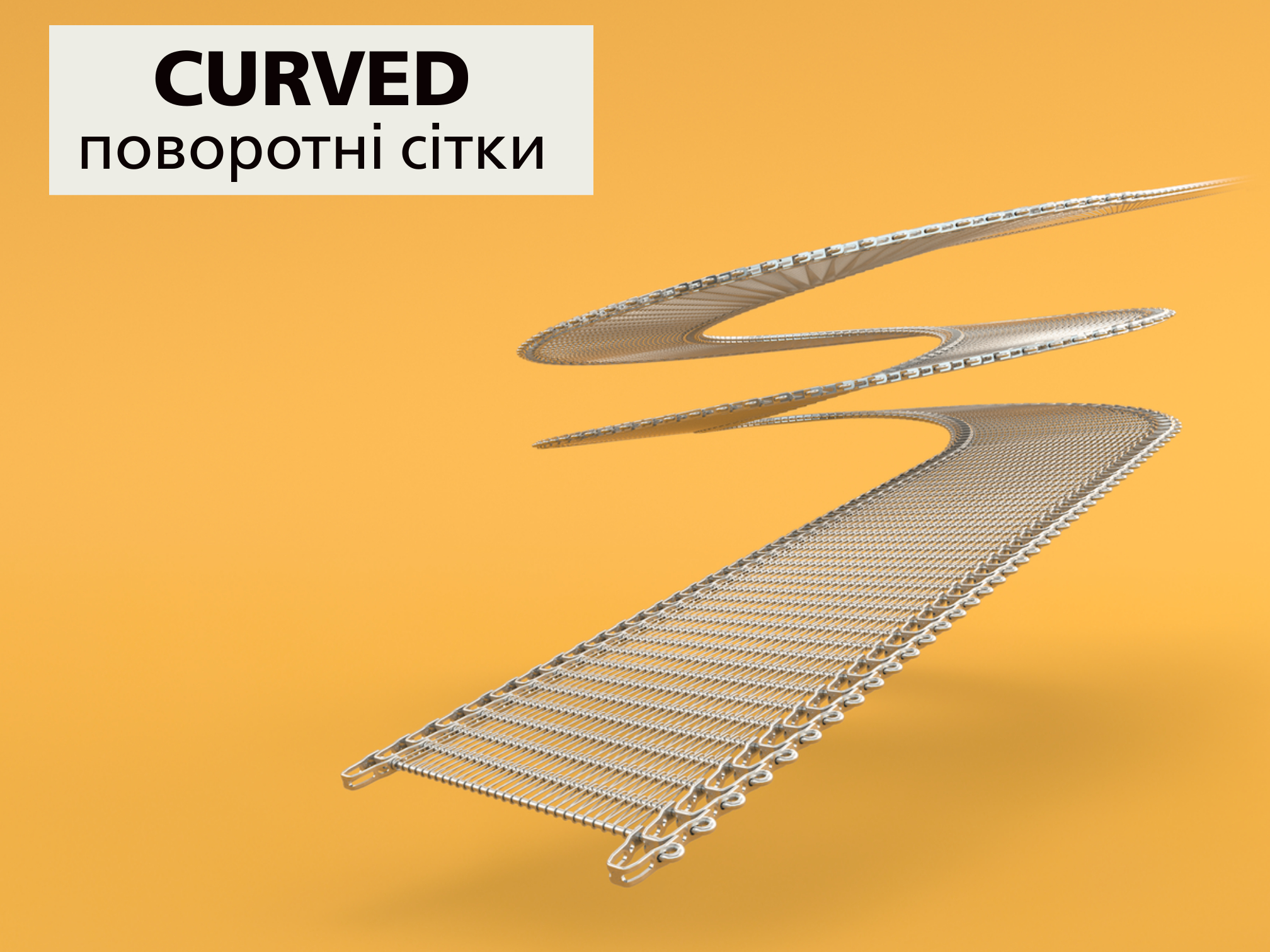

Curved conveyor belt

Manufactured from metal wire and cross rods, with special chain links on the sides. This design provides flexibility in all directions, making the belt ideal for conveying on lines with both straight and curved paths.

Advantages:

• ensure smoother belt movement;

• easy to clean;

• reduce belt elongation;

• minimize system wear.

Applications: spiral freezers, cooling tunnels, conveyors in space-constrained environments.

Advantages of metal conveyor belts

🔹 High-temperature resistance. Withstand temperatures over 1000°C, making them suitable for use in heat treatment furnaces.

🔹 Chemical inertness. Stainless steel or specialty alloy belts are corrosion-resistant, even in aggressive environments.

🔹 Hygienic design. Easy to clean — a key requirement in food processing applications.

🔹 High strength and durability. Resistant to tearing, deformation, and wear.

🔹 Flexible construction. Customizable for specific tasks — from transporting small parts to moving heavy workpieces.

🔹 Energy efficiency. Certain belt types have low friction coefficients, reducing drive load and energy consumption.

Beltimport — your trusted metal conveyor belt supplier

Beltimport offers high-quality metal conveyor mesh belts from leading European manufacturers, with complete engineering support. We help you select the optimal solution tailored to your production needs.

Our partners include:

Twentebelt (Netherlands): over 100 years of experience designing metal belts for the food and chemical industries.

Pietro Bonaiti (Italy): specializes in premium wire mesh belts for heat treatment and material conveying.

WBT (Italy): manufacturer of a wide range of specialized metal belts for industrial transport.

Costacurta (Italy): a globally recognized expert in metal mesh technology with deep engineering expertise.

Wire Belt Company Ltd (UK): renowned manufacturer of metal conveyor belts since 1962, combining tradition, precision, and innovation with manufacturing facilities in the UK, USA, and Germany.

Looking for reliable metal conveyor mesh belts?

Contact Beltimport — we guarantee expert selection, premium service, and technical support every step of the way.

Comments