We have been manufacturing conveyor and transmission belts for over a quarter of a century. To produce high-quality belts promptly, we always maintain a warehouse stocks, employ highly-skilled workmen, utilize contemporary equipment and control quality at every stage of production. We closely monitor all market trends in belts to implement the best global practices.

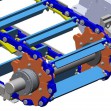

Our warehouse holds a wide range of top-quality materials for clients from various industrial sectors. To precisely match and calculate belts, we use specialized software. We receive the material for making belts in rolls that are 3 meters wide and 50 meters long. We cut the required belt size from the roll using specialized cutting machine. Next, if necessary, we proceed with the required type of belt splicing, involving supplementary equipment: for stamping, for layering, for grinding and heat presses. Additionally, we manufacture turning belts, weld crosswise/longitudinal profiles and corrugated sidewalls, provide of perforation holes in belts, perform installation of belts on equipment, conduct service inspections of on our products at customer facilities.