Problem:

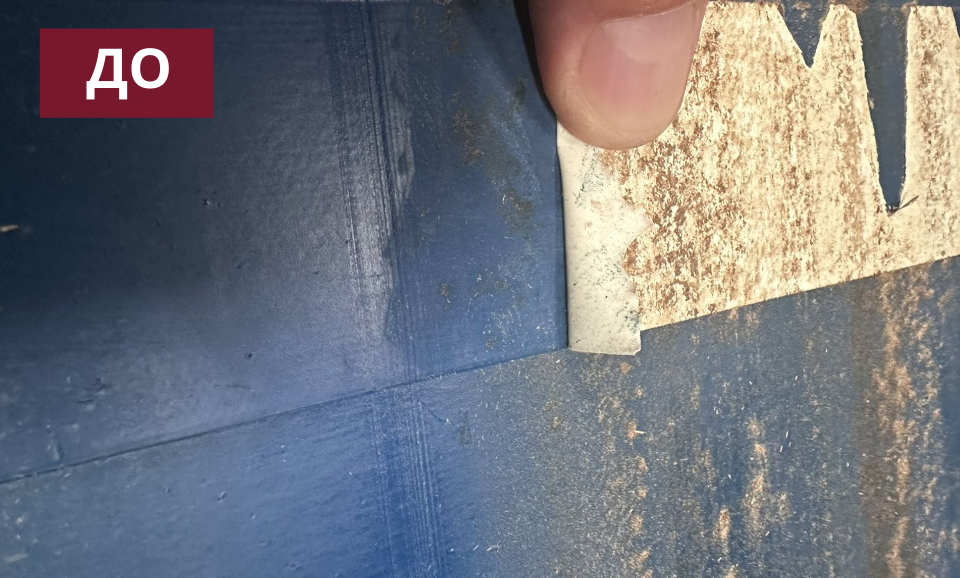

The delamination of a polyurethane marker for machine vision on the forming belt of a competing brand at a particleboard production line of a well-known panel manufacturer.

Due to the marker delamination, there were failures in reading the conveyor's revolutions by the machine vision system, and pieces of delaminated polyurethane foil in the process gets into products.

Since the entire process is controlled by a single management center, this conveyor belt issue disrupted the entire technological process of particleboard production.

Solution:

The company's specialists visited the client, analyzed the problem, and developed a plan and budget for the restoration work.

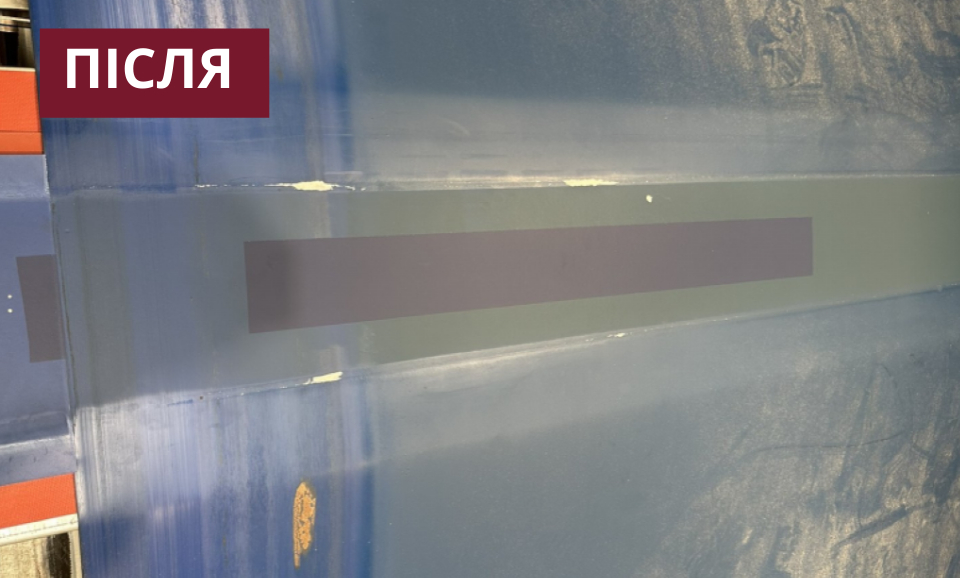

Since the top layer of the belt is most exposed to chemical reagents, resins, and physical wear, the damaged marker and the top layer of the joining area belt were removed first. In some areas, the marker was removed along with the top layer of the belt, which may indicate uneven melting of the marker foil into the belt. In sections where delamination occurred with the top cover, several repair films had to be soldered in to achieve the thickness needed to match the thickness of the belt.

Result:

Beltimport's service team restored operational capability and repaired damage to the existing conveyor belt, thereby preventing an emergency stop and equipment downtime.

The service life of the belt is increased until the moment of its scheduled replacement, which allows to use it without the need for unforeseen repairs or maintenance stops.