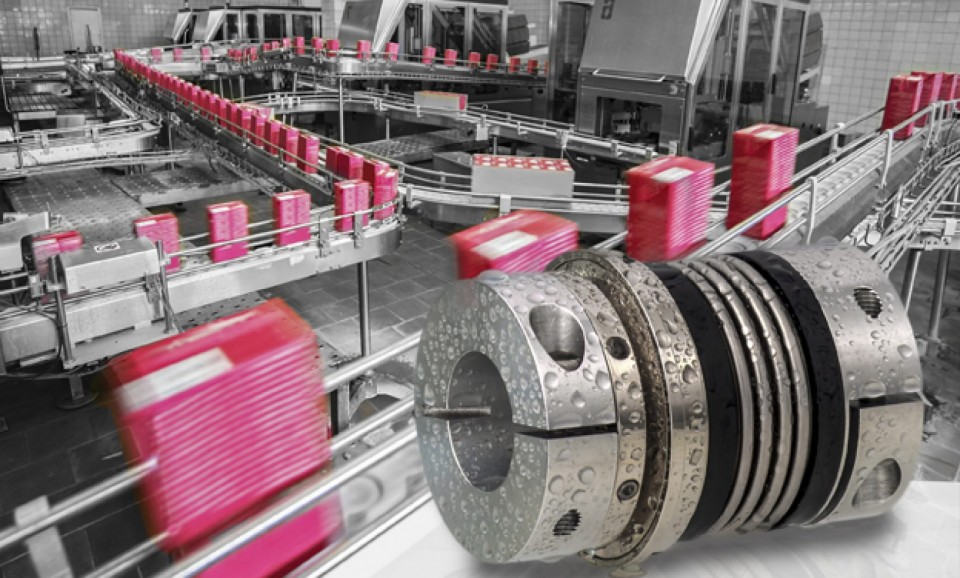

In the food processing industry, alongside hygiene, process reliability plays a crucial role in ensuring that finished products are of consistently high quality. Safety couplings from R+W (Germany) can help protect sensitive production lines from expensive breakdowns and damage to the machinery. A metal bellows made of highly elastic stainless steel is the heart of every metal bellow coupling. Metal bellows couplings are torsionally rigid and transmit torques from 15 to 10 000 Nm.

The couplings used in all of these production steps can represent decisive safety factors. The primary task of a precision coupling in mechanical and plant engineering is, as a rule, to ensure rigid and backlash free transmission while compensating for lateral, angular or axial shaft misalignment. At the same time, a very high level of operational reliability is an obvious requirement.

In the food processing industry, it is also necessary to fulfil hygiene requirements. That’s why R+W manufacturer uses only the highest quality stainless steel for couplings in this sector. Metal bellows couplings from R+W are especially effective when used to compensate for misalignment and protect from overload here, thanks to their high torsional rigidity and precise torque transmission with exact positioning accuracy. This makes them ideal for the sensitive machinery used in the processing of foods.

Thanks to long-term partnership between Beltimport and R+W Antriebselemente, the couplings can also be individually designed according to customer requirements. They are available in various options: balanced, static or dynamic, with flange mounting, with a keyway or mounted by clamping bush, or with welded joints if the couplings must withstand significantly higher moments or temperatures.