Statistics identify bucket elevators as one of the most potentially explosive areas in the process of raw material transportation. Approximately 30-40% of all industrial explosions caused by dust concentration occur in elevators. This is due to the transportation of easily ignitable bulk materials within enclosed systems, which leads to the formation of a dust mixture with oxygen — a potential source of ignition and explosion. To reduce the risks of ignition in explosive environments, relevant protection standards are continuously improved and adapted, and cutting-edge technologies are developed. One such technology involves fire-resistant rubber elevator belts.

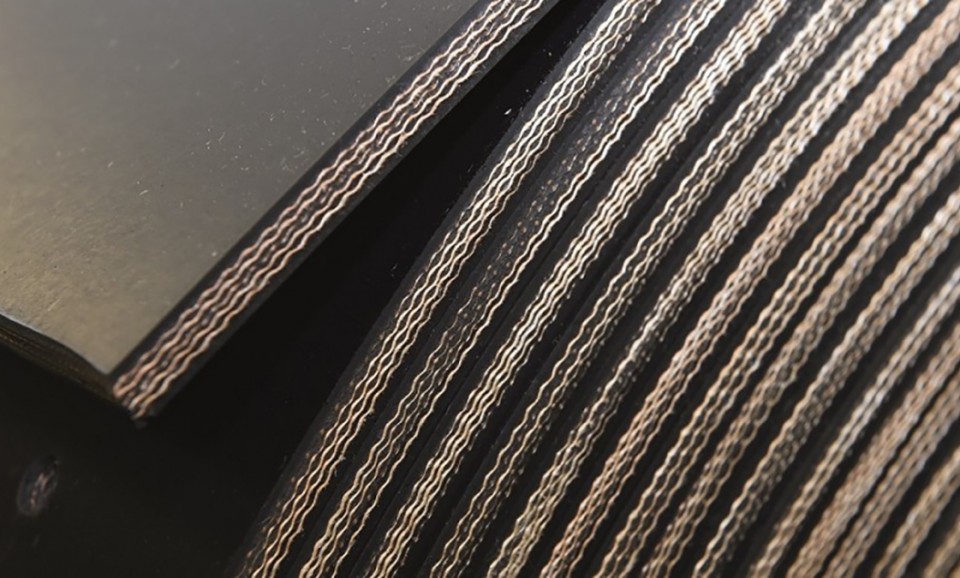

The antistatic elevator belt Polysur 275-K not only meets the requirements for electrical conductivity (ISO 284 / DIN 22104) and fire resistance (ISO 340 / DIN 22103), but it also demonstrates oil and grease resistance. As a result, Polysur 275-K not only addresses the issue of potential ignition but also boasts a long operational lifespan and significant resilience when working with oil-bearing crops.

For the technical specifications of the belt, please refer to THIS LINK.

The certificate of conformity for the belt can be found HERE.