Equipment manufacturers often want to use chains in pairs, usually in conveyors and transshipment stations, as well as in assembly, production and printing machines, when it is necessary to move parts with high accuracy and/or synchronously with other operations.

There are standards that establish tolerances for length accuracy, but they do not cover the assembly of segments in long chains. Therefore, there is a possibility of a significant error accumulating if the chain length includes several segments that are individually within the tolerance. The longer a chain is, the greater a possibility that it will have a significant accumulated error. Some manufacturers solve this problem by sorting their chain segments into two or three classes of greater accuracy, although the probability of accumulated errors remains.

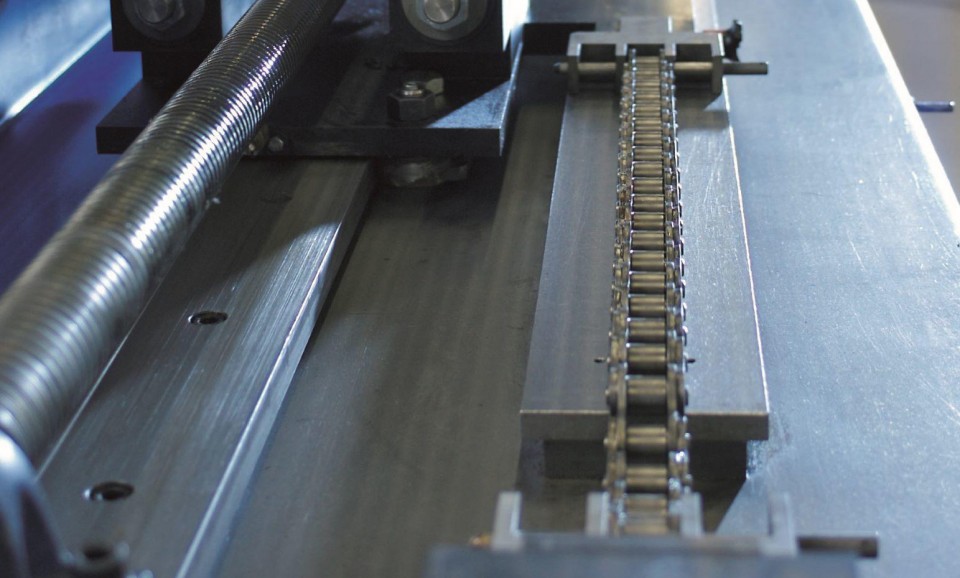

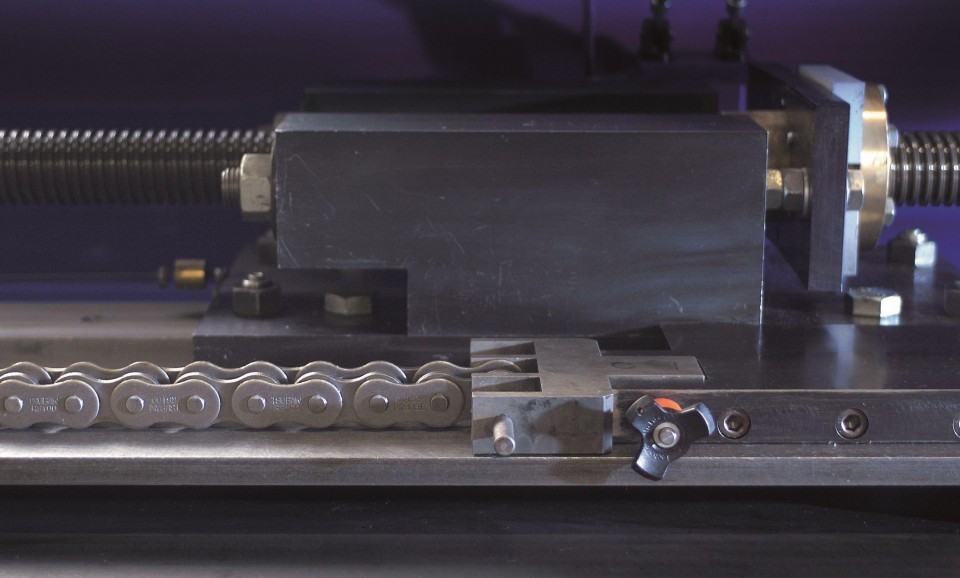

Tsubaki, the leader in chain production, solves this problem on a new level with Match & Tag, which ensures that paired chains are the same length with a tolerance of 0.50 mm, regardless of the total chain length. This means that they will be correctly installed and provide a long service life without worrying about inaccurate operation, uneven wear and re-tensioning. The Match & Tag service uses the very sophisticated measuring equipment of Tsubaki European headquarter, which additionally ensures short delivery times. However, the highly accurate history of chains actually begins with the manufacture of parts and their assembly. The tolerances on the physical dimensions of each element of the chain are tight, as are the quality of the raw materials used and the control of processes such as heat treatment. That`s all ensures that tolerance deviations are absolutely minimal.

Beltimport offers Match & Tag service for Tsubaki single-row chains of BS standard from RS08B to RS32B, ANSI standard from RS40 to RS100, including Heavy Duty series, and also for ANSI double-row chains from RF2040 to RF2100. Upon an additional request, it is possible to discuss the provision of services for other sizes of chains, as well as monitoring the compliance of chains with special requirements.