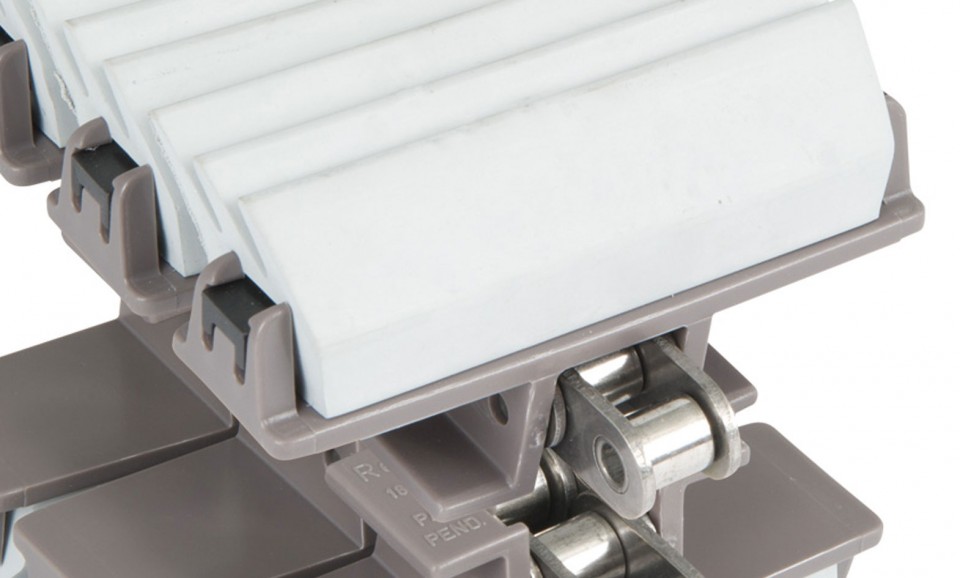

Gripper (grip) chains are made on the basis of standard roller chains with attachments with rubber pads for fragile products transporting. Gripper chains are widely used in the beverage filling industry, especially in ionization and bottle washing processes, in elevators and descending conveyors. For the last few years, the speeds of the lines have doubled and due to these high speeds and high loads, the requirements for chains with rubber grippers have significantly increased.

In response to this, Rexnord has released a new and improved 1873 SideGrip series chain with grippers that are 12 mm higher than the standard ones. The gripper material ensures reliable, fault-free operation at high speeds. The new larger grippers have more flexibility which helps protect bottles during transportation. Combined with a new and enhanced stainless steel roller chain with the FDA approved food grease lubrication, the Rexnord 1873 SideGrip Chain has a significantly extended service life.

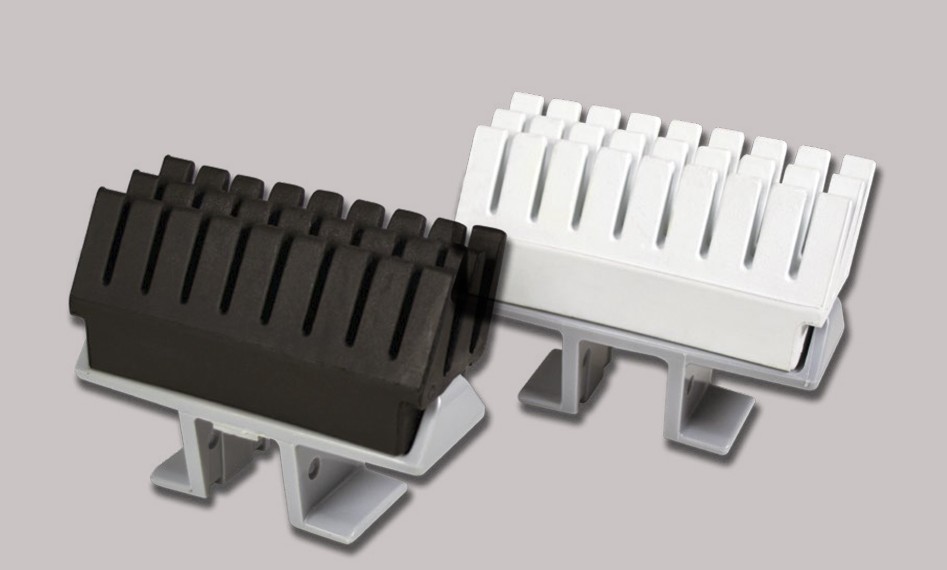

The cover material is available in two versions:

- A softer 40 Shore A black neoprene for more flexible bottle grip.

- More rigid 50 Shore A white synthetic rubber for heavier applications or abrasive environments.

If you are designing a conveyor or upgrading an existing one, Beltimport specialists will advise and help select the best option. Do not hesitate to contact us.