Problem:

Due to a combination of high temperatures and the influence of oil, the belts that were used for conveying oil-containing raw materials, fail every 3-4 months. Belts fail result in the equipment stops to replace the belts, the need to keep belts in case of accidents, as well as constant replenishment of their stock and have a negative effect on the financial performance of the production.

Solution:

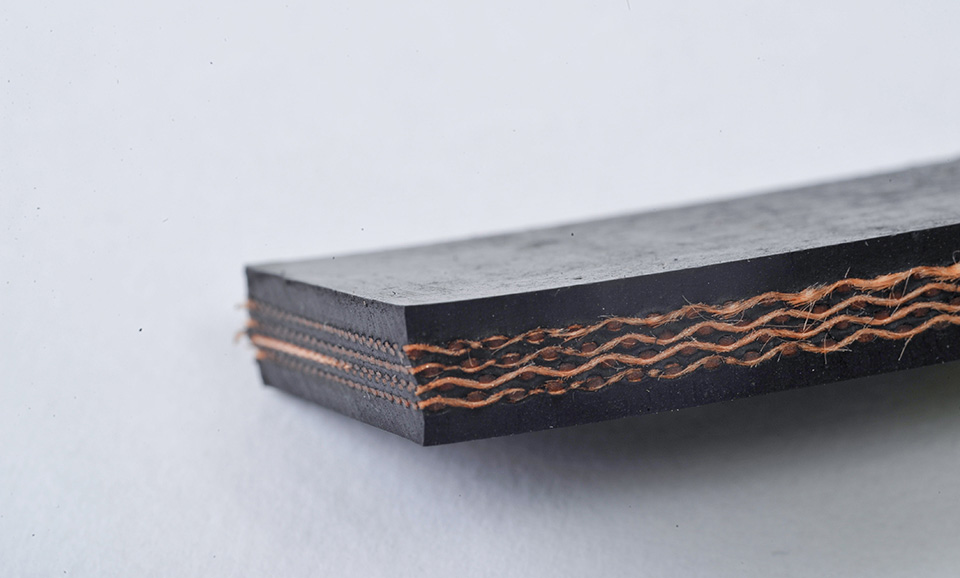

It is recommended to use Muller Beltex belts, POLYSUR Type 278 series, made with a polyamide base and covers made of special compounds. These POLYSUR belts are capable of simultaneously withstanding temperatures up to + 120 ° C and the effects of oils / fats, while having anti-static and self-extinguishing properties. Following the recommendation to change the existing belts to POLYSUR type extended the belt life up to 2 years. The maintenance costs of the bucket elevator have been significantly reduced. The financial indicator of the efficiency of this production area has reached the target value.

Result:

Equipment stops associated with the need for repairs and maintenance of the bucket elevator are excluded, the service life of belts is increased by 10 times - from 3 months to 2 years.