Chains, Sprockets, and Couplings for Operation in Aggressive Conditions of the Cement Industry

Cement is an essential and integral component in the construction sector, providing strength to various structures and constructions since ancient times. In the modern world, the increasing demand for cement drives cement equipment manufacturers to enhance the reliability of cement machinery. One of the key players in this arena is Tsubaki, a company offering dependable and durable solutions for conveyors designed to operate in the aggressive conditions of cement production.

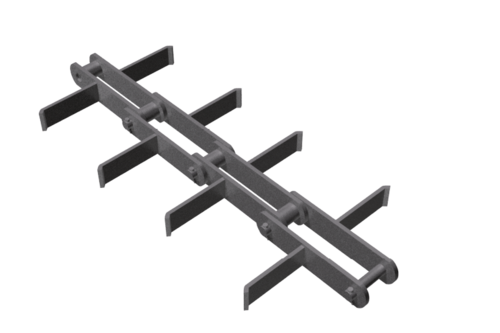

- Bucket Elevator Chains

High technical standards for chains require innovative technical solutions. Tsubaki's production chains combine high strength with protection against abrasive and corrosive influences. These attributes are achieved through technological solutions such as using high-quality alloy steels for chain element production, employing specialized methods and thermal treatment regimes, applying additional coatings to chain element surfaces, and utilizing seals between connected elements. The development and manufacturing of Tsubaki chains for bucket elevators are the result of meticulous engineering aimed at high reliability and product durability. These chains ensure reliable performance under high loads in aggressive conditions that demand special attention during their design. Usually, chains are manufactured according to the specifications of the BT series. However, for special solutions, Tsubaki offers the FB, FBXA, and WORKHORSE series. Unique features of these conveyor chain series include:

- FB: This series features special lubrication between pins and bushings, as well as specialized sealing elements between inner and outer links.

- FBXA: It includes roller hardening along with all the advantages of the FB series.

- WORKHORSE: This chain series involves high-quality press fitting of its elements, providing high resistance to fatigue wear. Additionally, it incorporates coated pins and bushings, special seals that protect chain bearing sets from abrasive and corrosive wear.

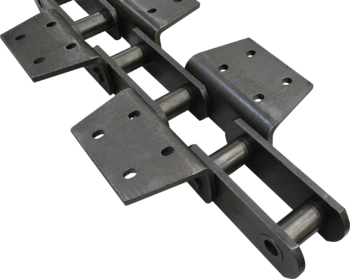

- Reclaimer Chains

Tsubaki offers reclaimer chains with various options tailored to the unique challenges of your operations. These chains are designed to excel in dusty environments, combating abrasive particles between bushings and rollers. Tsubaki provides chains made from diverse materials, using special coatings for elements, a wide array of fasteners, and rollers. Reclaimer chains require a large bearing surface area, high hardness, and deeply hardened surfaces. Tsubaki's engineers apply these principles when developing reclaimer conveyor systems with chains and sprockets, ensuring prolonged equipment service life.

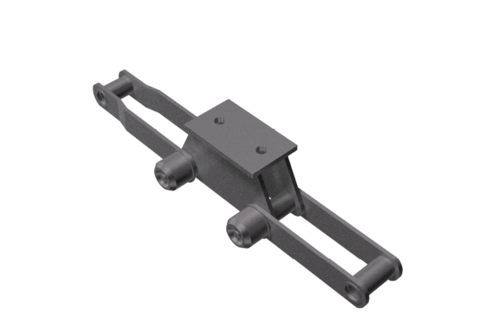

- Inclined Conveyor Chains

Chains designed for use in inclined conveyors from Tsubaki are characterized by high rigidity and an anti-deflection design that guarantees reliability not achievable by standard equipment manufacturer chains. However, Tsubaki doesn't stop there - they also ensure impeccable uniformity between two parallel chains, ensuring even load distribution during chain operation. Tsubaki's precision assembly goes beyond the industry's usual standards, enabling maximum conveyor efficiency and reliable, durable conveyor operation.

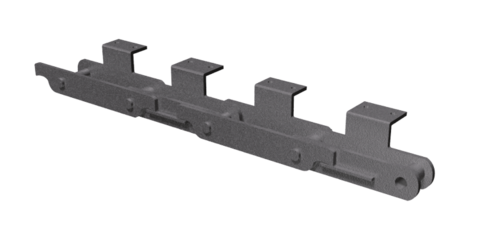

- General-Purpose Conveyor Chains

Tsubaki takes pride in its extensive lineup of chains for large-scale conveyors. These chains can be tailored to individual requirements, manufactured using various materials, combinations of heat treatments, coatings, corrosion resistance, attachments, and roller types.

- Drive Chains

In harsh environments with dust and abrasive particles, standard chains have shorter service lives. Tsubaki's solution - the Titan series chain - is designed for extended service life in aggressive conditions, such as cement plants. Tsubaki Titan features seamless sleeves with lubricating grooves, specially coated pins, nickel-plated outer plates, inner plates with black oxide, and special "ring coin" indents on plates, maximizing the chain's longevity.

- Sprockets and Traction Wheels

The chain-sprocket pairing should function as a harmonized system. Tsubaki's sprockets are crafted from high-quality materials and feature extra hardening of tooth surfaces, resulting in longer chain life. Tsubaki offers a wide range of sprocket designs that enable quick assembly and disassembly without the need to dismantle the drive shaft assembly.

- Backstop Clutches

Tsubaki's BS-F backstop clutches are designed to prevent reverse transmission of torque, which could lead to equipment damage and subsequent repair costs, in environments with dust and abrasive particles. The construction of these clutches allows the inner ring to rotate freely in one direction. In the case of reverse torque, the mechanism of the outer ring engages, instantly preventing further torque transmission in the opposite direction. Tsubaki BS-F clutches are specifically developed for demanding operating conditions and are an optimal solution for inclined cement plants.

.png)

The cement industry demands high reliability and endurance in its equipment. Tsubaki addresses this challenge by offering diverse solutions for various aspects of cement production. Their technological innovations in chains, clutches, sprockets, and other equipment help enhance productivity, reduce wear, and ensure reliable operation even under the most challenging conditions.

Overall, Tsubaki is a significant player in the cement industry equipment market, thanks to its combination of innovative technologies and experience in developing solutions aimed at achieving optimal equipment productivity, strength, and durability.

Comments