Surface structure influence on the operational properties of tapes

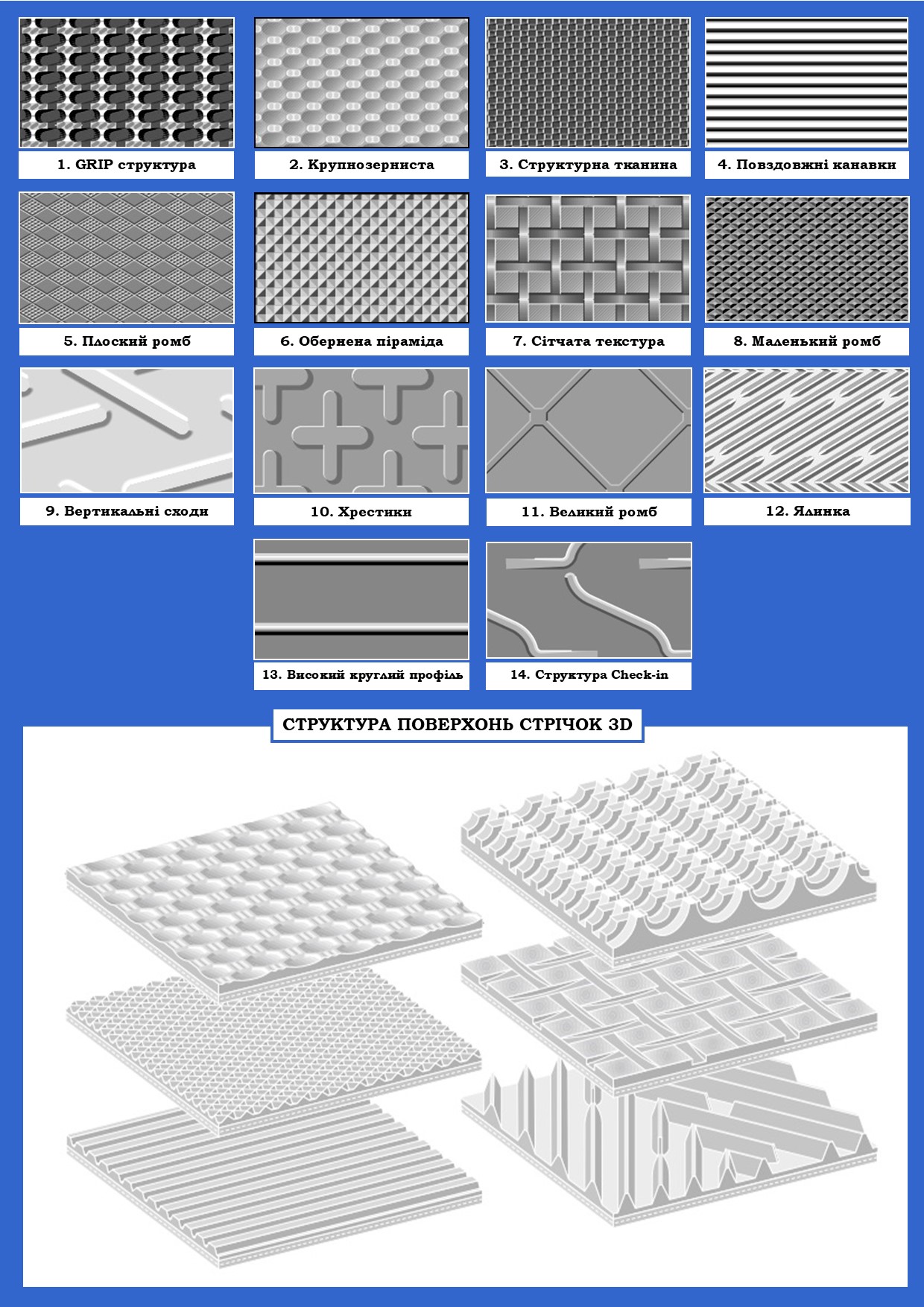

Polymer belts used by the production of various industries have their own certain differences and features of use. With the growth of the range of belts, the concept of universality is mostly leveled off. In addition to the usual matte and glossy surfaces, conveyor belt manufacturers offer structured or textured surfaces that have certain properties for the respective industries.

.png)

A smooth, rough or textured surface is a stress concentrator that accumulates in the "belt-product" contact zone. This parameter refers to the microgeometry of the material and is an integral part of the operational characteristics of polymer belts.

The geometry of the surface includes not only the drawing (print) of the texture, but also the thickness and quality of spraying, which is mostly special, that is, not standard. The structure of the belt surface affects the following important operational properties:

- wear resistance;

- elasticity;

- noise;

- static and dynamic strength;

- durability of the coating;

- hydrophobicity;

- corrosion resistance;

- strength of the joint working under tension;

- coefficient of friction;

- static;

- visual component (color, type of structure, gloss, etc.).

Violation of the structure (wear) of polymer belts manifests itself in the following stages:

- Primary wear (period of grinding at the beginning of operation);

- Normal wear and (operational) tear, which occurs in proportion to time and loads;

- Emergency wear (unforeseen conditions, friction) occurs because of excessive kinematic forces or mechanical damage.

The special texture of polymer belts provides the following functional advantages:

- a possible (up to 30°) angle of inclination without using a profile;

- perfect adhesion to the cargo being transported in the range of application from the logistics center to dough transportation;

- embossing of a special pattern on the lower part of freshly formed semi-finished products, manufacturer's products, etc.

Polymer belts with any presented textured surface are available at the Beltimort company warehouse. In addition, when connecting the belts, our specialists duplicate the necessary texture on the joint segment in order to minimize the "transition" and simplify the visual effect on the line.

Comments