Polymer belts. Focus on hygiene!

Belts with PVC, PU and silicone coating are based on synthetic fabric cords. However, fabric reinforcing layers of polymer belts have weak points in terms of hygiene. It is important that there is no damage to the coating of belts, which is a source of bacterial growth. Because of damage to the belt edges due to friction and their hairiness, the fragments of threads get on the product, the hygienic properties of the belt are getting worse as well. The solution is to seal the belt edges with plastic.

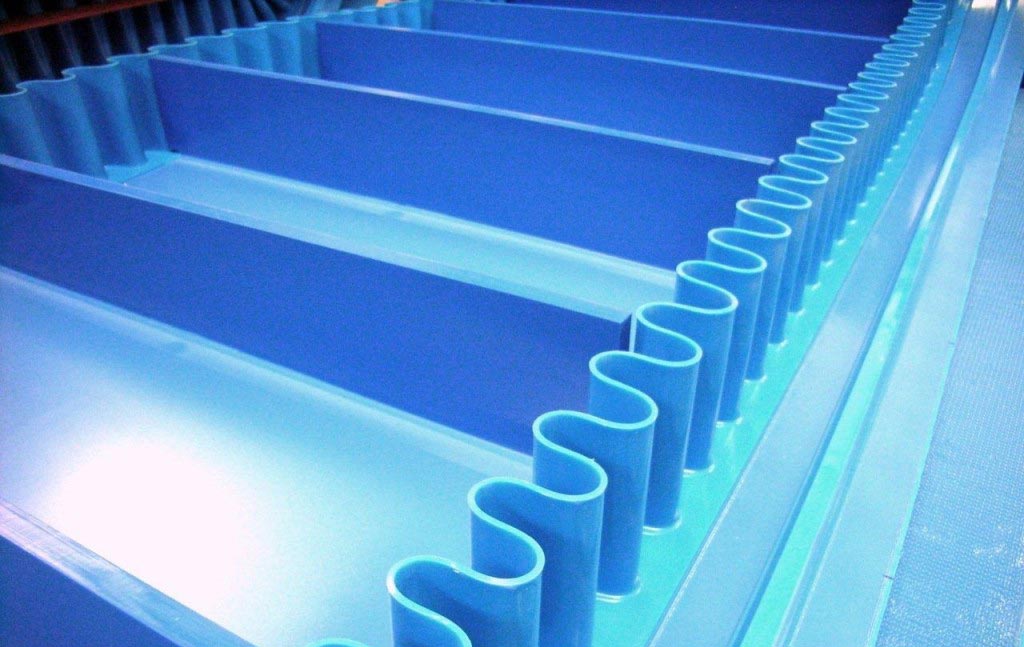

The possibility of applying corrugated sidewalls, cross and guide profiles allows to use the belts widely on straight horizontal and inclined conveyor sections. Cross profiles can be made of extruded plastic as well as to be reinforced with textiles. In this case, their edges should also be hermetically sealed.

Knee conveyer section require specially cut belts, what disallow the conveyor construction of complex geometry on one drive station.

Conducting sanitary processing of synthetic belts is not particularly difficult. It is possible to carry out both manual and CIP-washing. The design of the conveyor should allow tension release and cleaning of the belt from both the upper and lower sides. If the belt slips on the table, it is necessary to dismantle it before cleaning. After washing, the belt should be be dried and only then mounted on the conveyor and operated. It is important that the fabric cord of the belt remains dry during operation and does not create a favorable environment for the propagation of pathogenic microorganisms.

Additional guidelines for cleaning polymer belts will be featured in the following blogs. Ask your questions in the comments.

Comments